Enzyme Complex For Growing Pigs

- Starzyme

- China LiaoNing

- Within Two weeks afterreceivedthe order

- 150 Tons Permonth

1. The enzyme complex for growing pigs is a kind of functional product based on the physiological features, production performance and the dietary characteristics of growing pigs.

2. This enzyme complex product can decompose anti-nutritional factors in the feeds, improve feed conversion rate, regulate nutrient absorption, transportation and utilization, and accelerate protein synthesis. It can increase 15% of feed utilization raxte, reduce 2-4% of feed/meat ratio, and shorten 10-15 days to reach slaughter.

Main ingredients: Bacillus licheniformis, Bacillus subtilis, lactobacillus, xylanase, β-glucanase, phytase, cellulase, mannanase, protease, and amylase.

Product appearance: grey white powder

Main Features:

1. The enzyme complex for growing pigs is a kind of functional product based on the physiological features, production performance and the dietary characteristics of growing pigs.

2. Excellent procedures and advanced techniques ensure the microbial and enzymatic activities and stability during storage, transportation and usage.

3. It is a safe and reliable green product with no pollution, no drug residues, no drug resistance, and no side effects.

Main functions

1. This product can decompose anti-nutritional factors in the feeds, improve feed conversion rate, regulate nutrient absorption, transportation and utilization, and accelerate protein synthesis. It can increase 15% of feed utilization rate, reduce 2-4% of feed/meat ratio, and shorten 10-15 days to reach slaughter.

2. The enzyme complex can improve the gastrointestinal microflora, reduce gastrointestinal diseases, clear any toxins produced in vivo continuously, recover sub-healthy state caused by the use of antibiotics, and attenuate constipation or diarrhea.

3. The enzyme complex can inhibit reproductions of Salmonella spp. and pathogenic E. coli effectively, and reduce any diseases caused by stress.

4. The enzyme complex can reduce chyme viscosity, increase feed intake and reduce feed waste.

5. The enzyme complex can significantly improve the environmental sanitation and reduce respiratory diseases by lowering down the levels of ammonia, hydrogen sulfide and other harmful gases produced in the excretion.

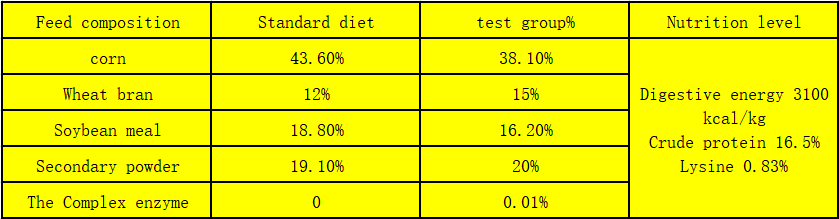

Experimental example

The compound enzyme applied to growing pigs.

Daily gain Feed ratio Relative feed cost

Control group Test group

Applications: This product needs to be added into feeds constantly at 1000 g/1000 kg of feed. When in use, premix and dilute gradually and uniformly into the feed. Use out as soon as possible after unsealing. For any unused part, close tightly and store under right conditions.

Package: 1000 g/bag

Storage: Store in dark, dry, cool (below 25°C) area with ventilation, and keep away from toxic and harmful materials.

Shelf life: 12 months

Analysis on the current pain points of the industry

1. False mark of enzyme activity

The product is marked with 100,000 enzyme activities, and the actual enzyme activity is 60,000, resulting in incomplete hydrolysis and indirectly increasing the cost of enzymes.

2. Product is unstable

Lack of enzyme protection technology and quality control, unstable enzyme activity, and differences in product specifications for each batch, resulting in product quality fluctuations.

3. Long production cycle

No enzymatic hydrolysis experience and enzyme compounding technology increase labor cost and R&D cycle, which indirectly affects the production schedule.

For us, our major is to solve these pain points

1. The enzyme activity can be customized, providing different enzyme activity products and solutions

2. Stable enzyme activity, unique enzyme activity protection technology to reduce fluctuations in production quality

3. Enzyme activity is not false, strict quality control links, third-party testing to reduce enzyme costs

Quality control strength

6 key control point inspections, escorting the whole process of quality, using extraction, membrane separation, vacuum freeze-drying, spray drying and enzyme activity protection technologies to produce products that fully meet the requirements of global customers.

Production capacity

Eight automatic primary fermentation cylinders (60 m³),

2 pure culture tanks (10 m³), 2 pure culture tanks (5 m³),

4 pure culture tank (4 m³), 2 pure culture tanks (1 m³),

4 pure culture tanks (0.3 m³), 1 large air compressors,

1 spray/drying tower (1 ton/h),

4 air drying and fluidized bed drying equipment

1 production line of ultra concentrate liquid enzyme.

The annual production capacity of the Starzyme is more than 20,000 tons of liquid, powd

Raw material grade single enzyme varieties that have been mass produced:

Xylanase (400000U/g) Cellulase (5000U/g)

β-Glucanase (30000U/g) Mannanase (50000U/g)

Phytase (100000U/g) High temperature resistant phytase (50000U/g)

Pectinase (30000U/g) Amylase (5000U/g)

Lipase (50000U/g) Acid Protease (50000U/g)

Neutral protease (100000U/g) alkaline protease (200000U/g)

Saccharification enzyme (300000U/g) Glucose oxidase (3000U/g)

High-end micro-ecological preparations that have been mass produced:

Bacillus subtilis (3×1011 CFU/g) Bacillus licheniformis (2×1011 CFU/g)

Bacillus coagulans (5×1010 CFU/g) Lactobacillus acidophilus (1×1010 CFU/g)

Lactobacillus plantarum (1×1010 CFU/g) Yeast (2×1010 CFU/g)

Enterococcus faecalis (1×1011 CFU/g) Clostridium butyrate (1.6×109 CFU/g)

Micro-ecological preparation for high-end organic fertilizer

Bacillus subtilis (1×1011 CFU/g)

Bacillus amyloliquefaciens (1×1011 CFU/g)

Bacillus coagulans (5×1010 CFU/g)

Enzyme preparation for alcohol and liquor

Saccharification enzyme: 200,000U/g

Thank you for your browsing, as a professional manufacturer of enzyme preparations and micro-ecological preparations, we are also very willing to help you . If you want to know the targeted solution, please leave a message in the message window below, we will assign a professional product consultant to contact you.