Enzyme For Wheat

- Starzyme

- China LiaoNing

- Within Two weeks afterreceivedthe order

- 150 Tons Permonth

1. The compound enzyme specialized for wheat mainly contains Arabian xylanase, β-glucanase and cellulase which can decompose the NSPs and their by-products in wheat significantly.

2. The feeds enzyme for wheat can improve the digestion and absorption of the nutrients in wheat based feed of livestock and poultry.

3. The feeds enzyme for wheat can increase 5% of the apparent metabolic energy of wheat and thus reduce the feed cost.

4. The feeds enzyme for wheat can increase 3% of crude protein and about 3% of amino acid value of wheat.

5. The enzyme activity can be maintained up to 90% when stored at room temperature for 6 months.

As the price of corn rises, wheat has become an important source of energy of feed. However, its wide application has been restricted due to its large content of non- starch polysaccharides (NSP, such as Arabia xylan and beta glucan, etc.) as anti- nutritional factors. The anti-nutritional effects of NSPs in wheat based diet can be effectively eliminated by addition of NSP enzymes. Better performance and lower feed cost can be achieved by replacing corn with wheat and adding enzymes in the dietary feed.

Main features:

1. The compound enzyme specialized for wheat mainly contains Arabian xylanase, β-glucanase and cellulase which can decompose the NSPs and their by-products in wheat significantly.

2. This compound enzyme is prepared based on the NSPs in wheat and their anti-nutritional effect.

3. Excellent post-processing, pelleting and coating techniques ensured the stability of the enzymatic activity during storage, transportation and usage.

4. It is a safe and reliable green biological product.

Main functions:

1. The feeds enzyme for wheat can improve the digestion and absorption of the nutrients in wheat based feed of livestock and poultry.

2. The feeds enzyme for wheat can increase 5% of the apparent metabolic energy of wheat and thus reduce the feed cost.

3. The feeds enzyme for wheat can increase 3% of crude protein and about 3% of amino acid value of wheat.

4. The feeds enzyme for wheat can improve environmental sanitation by reducing the moisture of feces and thus reduce the incidence of intestinal diseases.

5. The feeds enzyme for wheat can improve the growth uniformity of livestock and poultry.

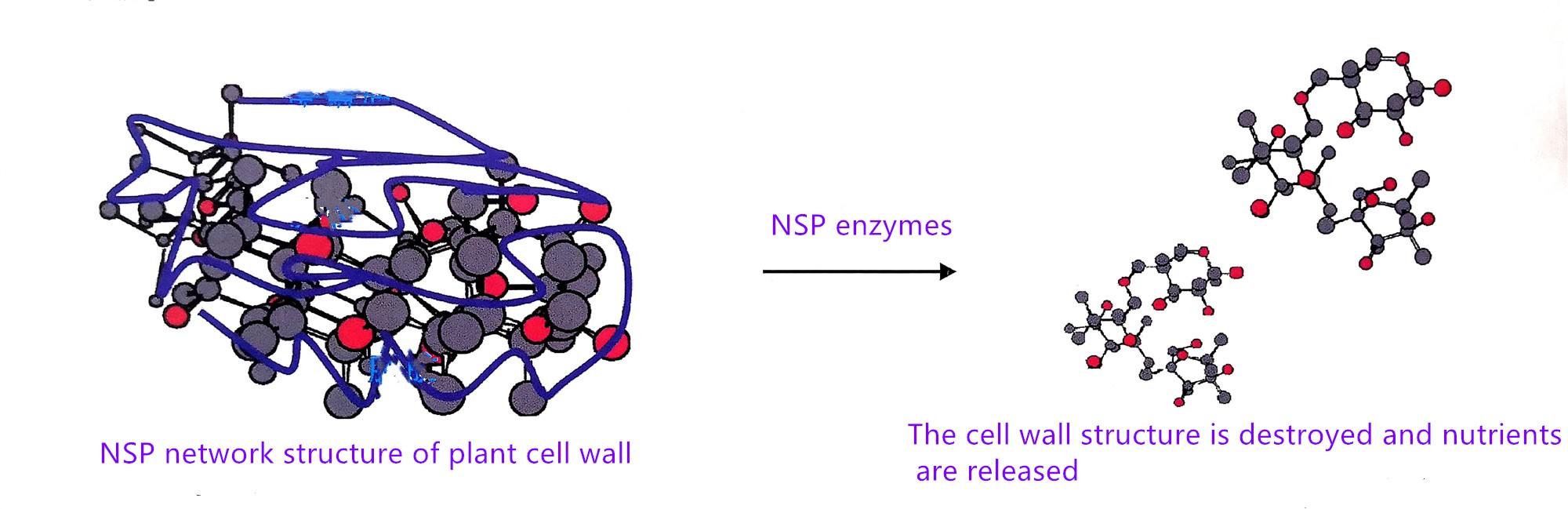

Compound enzymes (NSP enzymes) for wheat and its by-product diets. The mechanism of action of NSP enzyme

Destroy plant cell wall structure

The cell wall of wheat is mainly composed of NSP (arabinoxylan, β-glucan, etc.), and monogastric animals cannot secrete enzymes that degrade NSP. Adding NSP enzyme to monogastric animal feed can destroy the cell wall structure of wheat, release various nutrients wrapped by the cell wall, and fully contact the digestive enzymes in the animal’s intestines, thereby increasing the digestibility of various nutrients and improving the performance of livestock and poultry. Growth performance.

Reduce chyme viscosity

There are high-content and highly viscous water-soluble NSP in wheat diets. After entering the intestines, the viscosity of chyme increases, which slows down the rate of nutrient dissolution, and reduces the mixing speed of nutrients and intestinal digestive enzymes, so that nutrients are digested. The rate decreases, and causes the speed of chyme to pass through the digestive tract to decrease. Adding arabinoxylanase, β-glucanase and other NSP enzymes to wheat diets can hydrolyze highly viscous water-soluble NSP into polysaccharide fragments, which greatly reduces the viscosity of chyme, thus reducing nutrients and endogenous digestion The diffusion barrier of the enzyme disappears and the flow rate of chyme is increased. Thereby increasing feed intake, greatly improving the digestibility and absorption and utilization of nutrients.

Reduce post-intestinal microbial fermentation and reduce intestinal diseases of livestock and poultry.

NSP enzyme can reduce the accumulation of nutrients in the intestinal tract caused by reduced digestibility, change the internal environment of microbes in the intestinal tract, thereby indirectly inhibit harmful bacteria, reduce chick diarrhea, piglet diarrhea and other intestinal diseases, and improve livestock Growth performance of poultry.

Improve the activity of endogenous digestive enzymes

NSP can inhibit the activity of endogenous digestive enzymes, thereby reducing nutrient digestibility. The NSP enzyme is added to wheat diets to degrade NSP, eliminate its inhibitory effect on intestinal digestive enzymes, and improve nutrition.

Digestibility of minutes.

Applications:

The compound enzyme is suitable for feeds containing wheat, wheat middling and wheat bran. This compound enzyme should be used when the dietary feed containing 20% of wheat or 30% of corn is replaced by wheat.

1. Concentrate powdered enzyme: It is suitable for compound feed and concentrate feed and should be added at 100-150 g/ton of feed.

Package: 20 kg/bag.

2. Concentrate pelleted enzyme: It is suitable for supper concentrated feed and pelleted feed and should be added at 100-150 g/ton of feed.

Package: 25 kg/bag.

3. Concentrate coated enzyme: It is suitable for pelleted feed and premix and should be addedat 100-150 g/ton of feed.

Package: 25 kg/bag.

Storage:

Store in dry and cool (below 25°C) area with ventilation. During transportation, keep away from any toxins or harmful materials. Avoid direct exposure to strong sunlight, rain and moisture. The enzymes will lose activity at high temperature or under strong sunlight. The enzyme activity can be maintained up to 90% when stored at room temperature for 6 months.

Analysis on the current pain points of the industry

1. False mark of enzyme activity

The product is marked with 100,000 enzyme activities, and the actual enzyme activity is 60,000, resulting in incomplete hydrolysis and indirectly increasing the cost of enzymes.

2. Product is unstable

Lack of enzyme protection technology and quality control, unstable enzyme activity, and differences in product specifications for each batch, resulting in product quality fluctuations.

3. Long production cycle

No enzymatic hydrolysis experience and enzyme compounding technology increase labor cost and R&D cycle, which indirectly affects the production schedule.

For us, our major is to solve these pain points

1. The enzyme activity can be customized, providing different enzyme activity products and solutions

2. Stable enzyme activity, unique enzyme activity protection technology to reduce fluctuations in production quality

3. Enzyme activity is not false, strict quality control links, third-party testing to reduce enzyme costs

Quality control strength

6 key control point inspections, escorting the whole process of quality, using extraction, membrane separation, vacuum freeze-drying, spray drying and enzyme activity protection technologies to produce products that fully meet the requirements of global customers.

Production capacity

Eight automatic primary fermentation cylinders (60 m³),

2 pure culture tanks (10 m³), 2 pure culture tanks (5 m³),

4 pure culture tank (4 m³), 2 pure culture tanks (1 m³),

4 pure culture tanks (0.3 m³), 1 large air compressors,

1 spray/drying tower (1 ton/h),

4 air drying and fluidized bed drying equipment

1 production line of ultra concentrate liquid enzyme.

The annual production capacity of the Starzyme is more than 20,000 tons of liquid, powd

Raw material grade single enzyme varieties that have been mass produced:

Xylanase (400000U/g) Cellulase (5000U/g)

β-Glucanase (30000U/g) Mannanase (50000U/g)

Phytase (100000U/g) High temperature resistant phytase (50000U/g)

Pectinase (30000U/g) Amylase (5000U/g)

Lipase (50000U/g) Acid Protease (50000U/g)

Neutral protease (100000U/g) alkaline protease (200000U/g)

Saccharification enzyme (300000U/g) Glucose oxidase (3000U/g)

High-end micro-ecological preparations that have been mass produced:

Bacillus subtilis (3×1011 CFU/g) Bacillus licheniformis (2×1011 CFU/g)

Bacillus coagulans (5×1010 CFU/g) Lactobacillus acidophilus (1×1010 CFU/g)

Lactobacillus plantarum (1×1010 CFU/g) Yeast (2×1010 CFU/g)

Enterococcus faecalis (1×1011 CFU/g) Clostridium butyrate (1.6×109 CFU/g)

Micro-ecological preparation for high-end organic fertilizer

Bacillus subtilis (1×1011 CFU/g)

Bacillus amyloliquefaciens (1×1011 CFU/g)

Bacillus coagulans (5×1010 CFU/g)

Enzyme preparation for alcohol and liquor

Saccharification enzyme: 200,000U/g

Thank you for your browsing, as a professional manufacturer of enzyme preparations and micro-ecological preparations, we are also very willing to help you . If you want to know the targeted solution, please leave a message in the message window below, we will assign a professional product consultant to contact you.